Distributed recycling: an alternative for some biodegradable bio-based plastics

By Freddys R. Beltrán, Marina P. Arrieta, Jorge Ramírez, María U. de la Orden, Joaquín Martínez Urreaga, Universidad Politécnica de Madrid and Universidad Complutense de Madrid, Spain.

Picture 1: 3D printing wastes recycling equipment in “Fabrication Lab Circular” at UPM.

Biodegradable bio-based plastics have emerged as an alternative to petroleum-based, non-biodegradable plastics, with the main objective of lowering the environmental impact of the growing plastic consumption. However, choosing an adequate end-of-life scenario for these materials is key for keeping their low environmental impact.

In this context, the possibility of mechanically recycling these materials can both reduce waste and recover valuable raw materials, following the principles of a circular economy. However, this is a complex and expensive process, including many stages such as waste collection, grinding, sorting, washing, and re-processing. Mechanical recycling is traditionally carried out in large facilities, which are designed to manage the immense flow of conventional plastics which are most commonly used, such as PET (polyethylene terephthalate) or PE (polyethylene).

This leads to a problem: because biodegradable bio-based plastics represent only a small share of the plastics market, it is economically unviable to recycle them in large scale, since then it would be necessary to build dedicated infrastructure, which is very costly. This could be overcome if, instead of a centralized mechanical recycling approach, a distributed one could be adopted, in which each consumer (or small group of consumers) recycles their own plastic waste. This would also save energy and emissions, since less waste would need to be transported.

How could this look like? Let us take the example of poly (lactic acid) (PLA), one of the most commonly available bio-based and biodegradable plastics. Restaurant chains, grocery stores, and shopping centers could collect, clean and recycle their own PLA packaging waste.

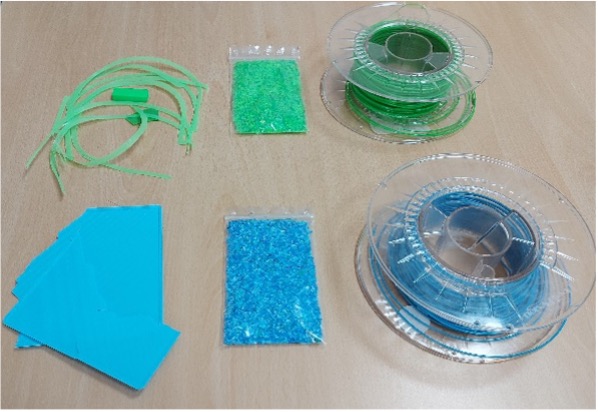

Picture 2: 3D printing filament made from recycled PLA wastes.

PLA is also widely used in 3D printing. Significant amounts of PLA waste are generated in universities and educational centers. Previous studies have shown that, if properly recycled, PLA can be successfully used for 3D printing. With this in mind, the Industrial Engineering School of UPM is currently developing a laboratory which is collecting, washing, and reprocessing 3D printing wastes into new filaments which can be used in 3D printing applications.

In summary, distributed recycling systems open the door to mechanically recycling some bio-based and biodegradable plastics, helping overcome the economic barriers of the recycling process.

If you wish to read more

The paper "Technical Evaluation of Mechanical Recycling of PLA 3D Printing Wastes", published by the BIO-PLASTICS EUROPE team on the journal Polymers is available at our downloads page.