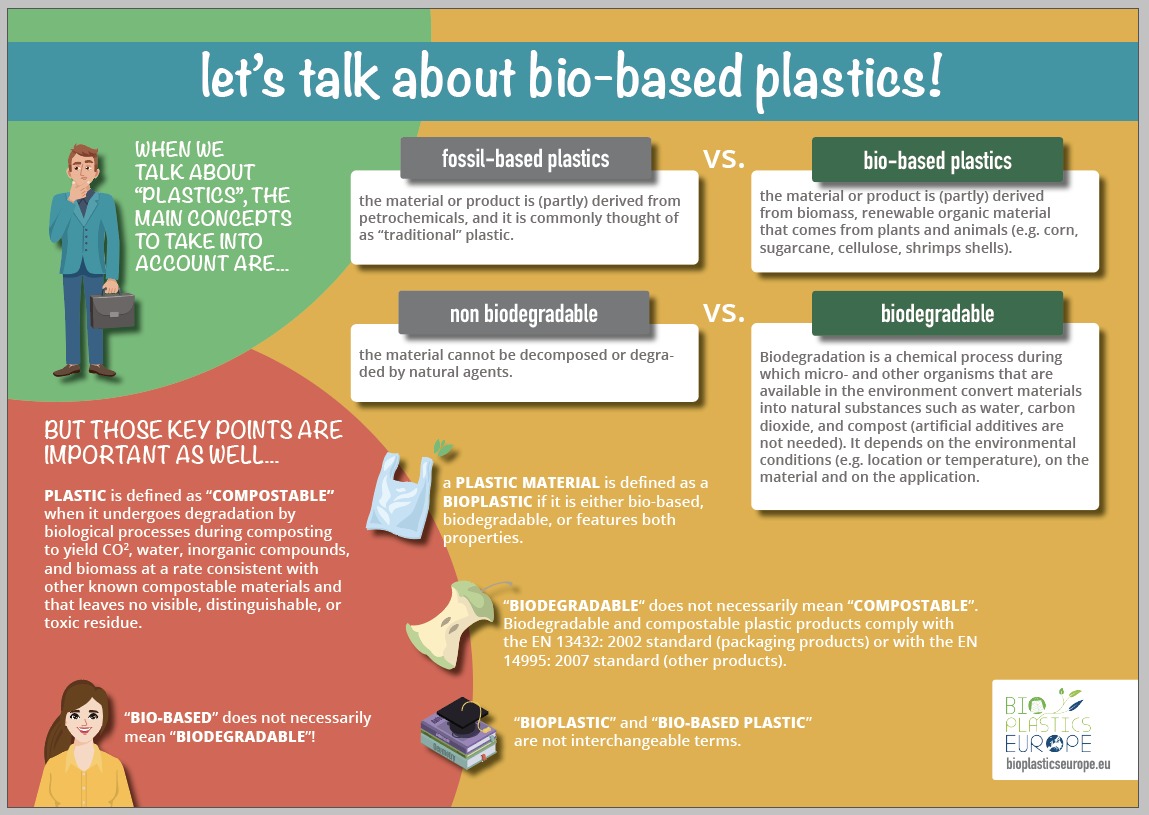

Plastics produced from renewable resources are often referred to as bio-plastics or biopolymers. However, the term "bio-plastics" is not precisely defined. It is commonly used to describe a variety of materials that consist, at least partially, of bio-based (renewable) feedstock and/or are biodegradable.

You can learn more from this short video developed by our partner ECOEMBES: What are Bio-based plastics

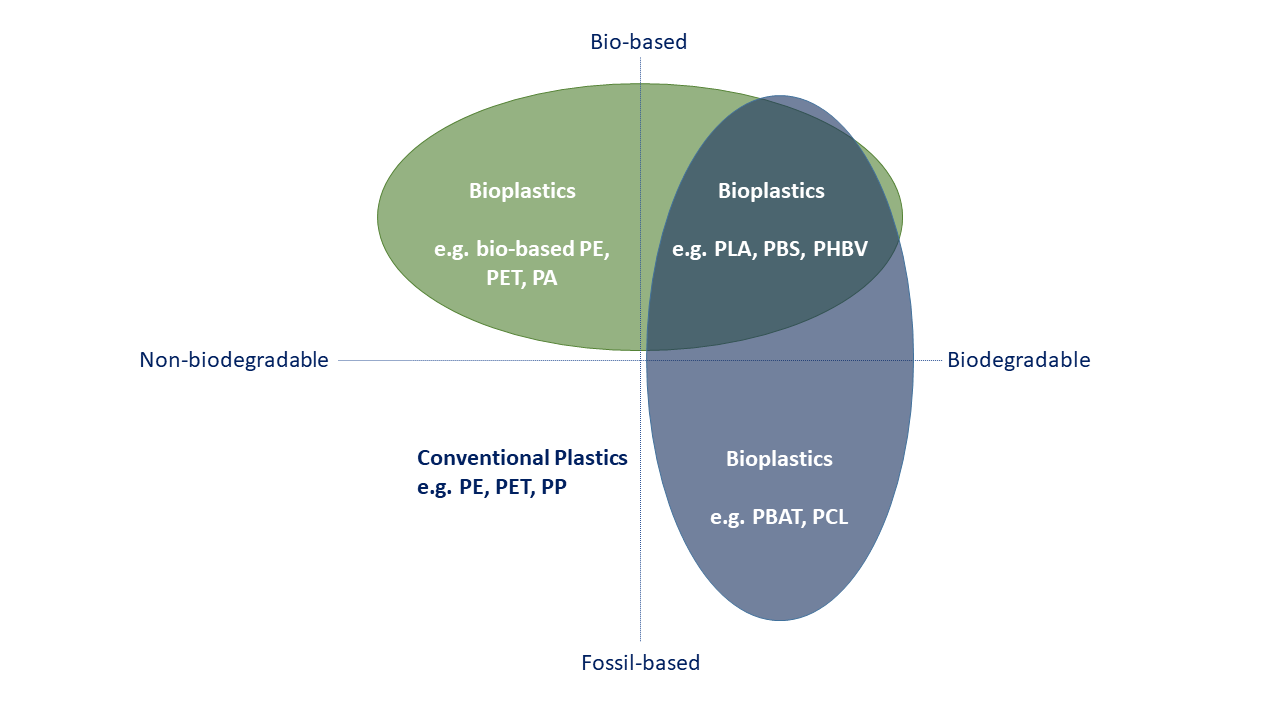

The following graph illustrates the different properties of plastic materials according to their biodegradability and origin.

Image source: European Bioplastics e.V. (EUBP)

The tem "bio-plastics" refers to polymers which are bio-based, biodegradable, or both.

We at BIO-PLASTICS EUROPE are looking only into polymers that are both bio-based and biodegradable. But what do those terms mean?

Bio-based: This means that a material is (at least partly) derived from biomass, that is, organic material of biological origin (excluding material embedded in geological formations and/or fossilized). Examples of biomass are plants, trees, algae, marine organisms, micro-organisms, animals, etc. "Bio-based" can also mean that the feedstock used for producing a material derives from any form of organic waste.

Biodegradable: Materials are biodegradable if they can be converted into natural substances such as water, carbon dioxide and compost by different naturally occurring organisms. In most cases, microbiological biodegradation is the most important process. Biodegradation is strongly dependent on the conditions for the microorganisms in water and soil. Furthermore, the biodegradation process is dependent on the presence or absence of oxygen. The property of biodegradation does not depend on the resource basis of a material but is rather linked to its chemical structure. The term "biodegradable" does not specify neither the time frame nor the environmental conditions which are necessary for the natural degradation of the material.

Do not forget: the term "bio-based" does not equal "biodegradable"

The biomass used to produce bio-based plastics can be obtained from different feedstocks. Currently, bio-based plastics are most commonly produced from Carbohydrate-rich food plants, such as corn or sugarcane, or oily plants. These traditional agricultural crops are called first generation feedstock and are the most resource-efficient and cost-efficient way to produce bio-based plastics nowadays. However, the impacts caused by those crops on the environment and on people's lives has drawn concerns over their sustainability. Issues such as their competition with production of food and animal feed, land consumption, water use, pesticides and precarious conditions for both workers and local inhabitants abound. Raw materials obtained from agriculture and forestry are indeed renewable, but their supply is neither unlimited nor available at all times. There is no doubt that intensive agriculture and forestry have negative effects on the climate and the environment; therefore, a sustainable and resource-saving use of biogenic resources is necessary.

In the meantime, second and third generation feedstocks for bio-based plastics are being studied and developed. Progress is being made on procedures for using cellulosic raw material and non-edible by-products of food crops such as straw, corn stover, bagasse or organic waste (second generation feedstock). Second generation feedstocks are still linked to food crop market dynamics. Third generation feedstock for producing bio-based polymers refer to algae or non-agricultural waste.

Molecule chains with properties comparable to those of petroleum-based polymers are produced from renewable resources through the chemical process of cracking and re-polymerisation. Examples thereof are the fermentation of sugars derived from sugarcane and beets, or the hydrolysis of starch derived from corn. This produces ethanol, which can be used to produce a wide variety of biopolymers. Other materials produced through fermentation are, for example, lactic acid, n-butanol, acetone, and polyhydroxyalkanoates.

Some of the frequently used "bio-based plastics" and their properties are as follows:

PA, PE, PET:

PLA:

PHA:

PBS:

PHBV:

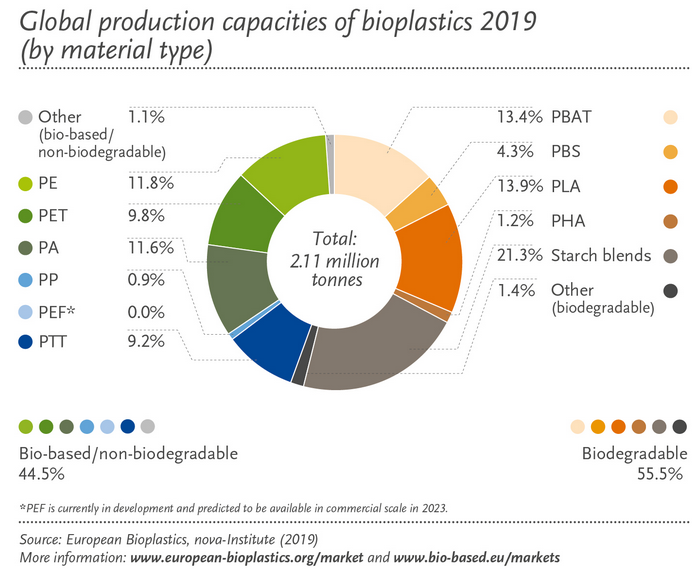

Bioplastics represented approximately 1% of the more than 359 million tonnes of plastic produced in 2019.

The bioeconomy as a whole and the market for bio-based and biodegradable plastics in particular are both supposed to grow, given that but not only because a sustainable & circular bioeconomy is a policy priority for the European Union. According to a market evaluation undertaken by European Bioplastic e.V. in cooperation with nova-Institute, the global bioplastics production capacity is set to increase from around 2.11 million tonnes in 2019 to approximately 2.43 million tonnes in 2024.

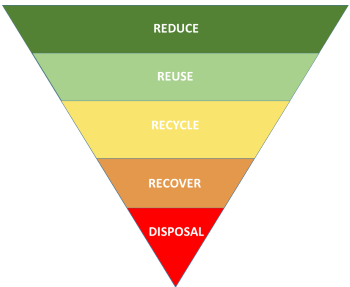

It is essential to talk about sustainable end-of-life solutions for bio-based plastics. Following the European waste hierarchy, reuse and recycling are preferred solutions to energy recovery or disposal.

The goal of this policy is to close the loop, meaning that the discarded product or material should be used again after its intended use. For bio-based plastics, there are two preferable ways to close the loop: recycling and composting.

The term "recycling" refers to the return of the waste which is generated by the production or by the consumption of a product into the economic cycle. This return may be effected through the reuse of the product or through its use as an input for the production of another product.

The main challenge for recycling is sorting the different types of bio-based plastics. As is the case for most conventional plastics, bio-based plastics need to be recycled in separate streams according to material type (e.g. PET-stream). Where a recycling stream for a specific plastic type is established (e.g. PE or PET), the biobased alternatives (bio-PE, bio-PET) can be recycled together with their conventional counterparts. For other materials such as PLA, there is no recycling stream established yet.

Compostability is the characteristic of a material that allows it to biodegrade under specific conditions (e.g. a certain temperature, timeframe, etc). These specific conditions are described in standards, such as the European standard on industrial composting EN 13432 (for packaging) or EN 14995 (for plastic materials in general). Materials and products complying with these standards can be certified and labelled as compostable. In order to make accurate and specific claims about compostability, the location (home, industrial) and timeframe of the process need to be specified. According to the EU standard EN 13432, a product is considered compostable if, among other things, it meets the following criteria under the conditions of an industrial composting plant:

Our team at the Hamburg University of Technology (TUHH) has conducted experiments on one of the PLA-based materials which have already been developed within the project. You can read about it here.